Manufacturing Process

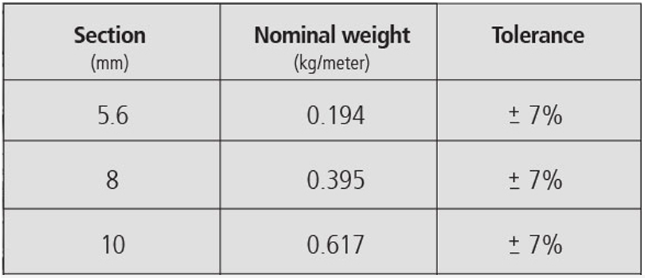

TopTech TMT Bars are manufactured from superior quality billets, in adherence  with the international quality standards and norms to ensure quality consistency. All billets are casted from first class ore sourced from high grade ore with exceptional chemical composition. The billets go through a test process to maintain the certified composition of Carbon, Sulphur and Phosphorus in the Rebar sections which makes them the best choice for construction.These are essential for being in compliance with tolerance parameters and high dimensional accuracy.

with the international quality standards and norms to ensure quality consistency. All billets are casted from first class ore sourced from high grade ore with exceptional chemical composition. The billets go through a test process to maintain the certified composition of Carbon, Sulphur and Phosphorus in the Rebar sections which makes them the best choice for construction.These are essential for being in compliance with tolerance parameters and high dimensional accuracy.

TMT Bar Features

Sturdy Build TopTech TMT Bars exhibit consistent superior strength and high ductility which ensures superior structures.Corrosion Resistant The controlled thermo mechanical treatment results in an uniform and thick tempered martensitic rim, completely free from internal stress.

This martensitic rim improves the corrosion resistance as well as fatigue strength.Seismic Resistance They support Seismic design due to its unique combination of strength, ductility and stress ratio.

Mechanical Properties

The advanced manufacturing process of TopTech TMT Bars makes it well surpass the minimum limit of strength and ductility specified in the standard IS: 1786. The yield strength also far exceeds the standard norms and specifications. The UTS/YS ratio and percentage elongation that determine the seismic property of a rebar, is also very high in TopTech TMT Bars. This significantly enhance its ability to handle the pressure of earthquakes.